|

|

| QUEST Home

- News and Events - New products |

|

|

Atlantium UV system

Atlantium Technologies Ltd., established in 2003, is at the forefront of next-generation UV (Ultraviolet) water treatment systems. It provides clean, green, safe and sustainable solutions for water dependent industries with high regulatory requirements such as Food & Beverage, Dairy, Bio-Pharma, Aquaculture, Municipal water suppliers, Power plants, Oil fields and Maritime. The company’s cost-effective and environmentally-friendly Hydro-Optic™ solution for UV water disinfection delivers unprecedented microbial inactivation, taking water safety to levels never before achieved with chemicals or other UV systems. It has been validated to the highest regulatory standards, including the FDA (US Food & Drug Association) and EPA (US Environmental Protection Agency). And it meets the stringent EPA standards for 5-log pathogen reduction and 4-log virus reduction.

|

|

Ci-Semi

CI Systems LTD founded in 1977, is a pioneer in a wide array of IR electro-optic (E-O) products for scientific, industrial and military applications. CI Semi is a division of CI Systems, which develops, manufactures, and markets in-line and in-situ monitoring solutions for the semiconductor, solar, and FPD manufacturing industry. WetSpec200 is using Flowcell Sensor design and PDA (Photo Diode Array) receiving core, using near infrared (Near IR) as the light source, through the calculation of IR spectra intensity of chemical liquid, checking-measuring curve matching pre-built (Calibration Curve), and then do a chemical analysis of the amount of liquid concentration.

|

|

Purafil

For over 40 years, Purafil has been the world leader in the engineering and manufacture of gas-phase air filtration media, systems, and air quality monitors. Purafil revolutionized the gas-phase air filtration industry with the development of the world’s first potassium permanganate, air-cleaning media. Today, Purafil is providing innovative, clean air solutions to customers in every geography and market. Purafil is supported by representative firms throughout the United States and over 60 countries.

In process industries, we are preventing corrosion of machinery and computer controls. In buildings, we are removing odors and improving indoor air quality. In museums, libraries, and archives, we are preserving art and historical documents. In cleanrooms, we are increasing yield and product reliability. In water and wastewater operations, we are protecting the environment. In postharvest shipping and storage, we are extending the life of fresh flowers and produce.

The Large Particle detector is a compact particle detector for applications in ultra pure and chemical aggressive media. The detection limit of 1 7um-particles makes this sensor particular suitable for in-line process monitoring and control of complex and high concentrated submicron dispersions, micro-emulsions or polishing slurries or even pure fluids.

|

|

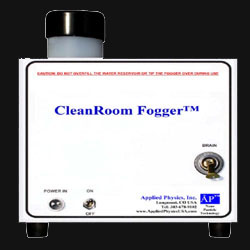

AP fogger

The CleanRoom Fogger™is a DI Water Fogger designed for low cost, easy to use visualization of airflow and turbulence with on/off fog control in clean spaces and around equipment. Fog visibility distance is based on airflow velocity and humidity around the fog. DI Water Foggers produce a 65 degree, visible vapor composed of microscopic DI water droplets (fog) at 10μm droplet size.

The fog is as clean as the DI Water or WFI Water used. 16 Meg Ohm DI water is typical while 64 Meg Ohm ultrapure DI water is ideal. The fogger cost is kept low for budget requirements. Ultrasonic transducers convert liquid directly to droplets and low water sensors protect the transducers during operation. Also provided is a visible fill level indicator to prevent water over fill. A standard power supply is provided at 115VAC or you may select a 220VAC operation. A flexible, corrugated, white fog tube can be oriented in any direction for fog directional output. For operator convenience the Operating Instructions, Application Notes and Specifications are labeled on the side of the fogger enclosure. 16 Meg Ohm DI water is typically used for Semiconductor and Pharmaceutical use. WFI water can also be used for Pharmaceutical applications.

|

|

PMT LPD

Large particle detection in pure fluids and in slurries

In-line Quality monitoring of CMP slurries

Prevention of micro scratches at polishing processes

Filter control

Optimization of filter lifetime

Ultra pure and chemical aggressive liquids

Low-cost quality monitoring of purified water

Defect detection in supply systems.

|

|

HALO KA\ ALOHA+\LASER TRACER3

Founded in 2001, Tiger Optics offers measurement at the speed of light. Based on Continuous Wave Cavity Ring-Down Spectroscopy (CW CRDS), Tiger Optics designs and manufactures dedicated trace gas analyzers and ambient air monitors for a myriad of molecular species and a wide range of matrices, including toxic, corrosive, and hydride gases. Our instruments serve an array of markets, from semiconductor fabrication to chemical synthesis to environmental monitoring, and more

Online, real time reading

Fast response

PPM to PPT

Accurate (Absolute)

Calibration-free

Low maintenance Low Cost Of Ownership

Intuitive user interface Transportable

|

|

|

|

|

|